Production

Trading House «TeplEko» has been the leading domestic manufacturer of monolithic quartz heaters for more than 10 years. All these years we are engaged both in creating our line of heating equipment and its sales. That allows Russians to buy our high-quality product at an affordable price, without markups.

The main complex of the company’s production facilities is located in the Kemerovo region. The capabilities of heaters TeplEko will impress you immediately after getting acquainted with their characteristics. The arguments in favor of the monolithic panels which delight heat are specific figures. They are achieved through the use of components of exceptionally high quality. We will talk about them below.

The success of the products of the brand “TeplEko” lies in the constant renewal of the plant’s production facilities. Ultra-modern equipment, qualified personnel, and multi-level control system are a guarantee of the unconditional quality of our quartz monolithic heaters supplied throughout Russia and former CIS countries. Employees of the company TeplEko constantly monitor the innovations in the global market of heating equipment, so all models of electric heaters meet international standards.

Unique quartz sand used by the company TeplEko

High-quality quartz sand, used for the production of glass (including optical and electric lighting), porcelain, crystal, dry construction mixtures, etc., serve as the basis for the manufacture of monolithic panels of electric heaters. Direct deliveries of raw materials suitable for our products are provided by Open Joint Stock Company (OAO) Quartz, which owns the unique Tashlinskoye deposit of one of the purest quartz sands in the world. The enterprise sends us more than 100 tons of purified natural sand every month. The contract for its supply was concluded due to the long-term cooperation of the company TeplEco with the Mining University (St. Petersburg).

Unique heating element used by the company TeplEko

One of the most important elements of any electric heater is its heating element. It has the highest temperature and, in general, determines the performance of the heat-emitting structure. A unique ovenproof and heat-resistant chrome-nickel heating element with high specific resistance and exceeding 98% efficiency has been developed for the companyTeplEko. Zigzag arrangement of the heater allows you to create a uniform heat flux over the entire surface of the monolithic panel. The heating element located inside the board is durable because it is not in contact with the external environment. Its designed service life exceeds 25 years.

Quality management in production

The company TeplEko united qualified developers and manufacturers, solving any problems in the field of electric space heating. The high quality of TeplEko thermal appliances is confirmed by the necessary certificates, voluntary and mandatory. Quality management certified according to international ISO standards is implemented in production. The priority task of Trade House "TeplEko" is the high-quality production of all components of electric heaters. At all stages of production, each batch of TeplEko products undergoes strict quality control: from the incoming inspection of purchased by the company materials to the packaging of heaters before shipment to consumers.

Technological stages of production

1. Preparation of raw materials

Initial components (quartz sand, refractory ecological binders, and additives) for the manufacture of monolithic slabs are stored in the indoor warehouse of the company. To increase the strength of the monolithic slab, high-purity quartz sand, as its main component, has several fractions.

At this stage, specialists in the factory laboratory carefully control the composition of the components. Its are pre-processed, sorted, and subjected to radiation control.

2. Mass preparation

To obtain a solution mixture the initial components are carefully prepared. The technology involves grinding, sifting, and weighing the components. Then the necessary proportions of components are mixed and fed into a unique installation (RBU), manufactured according to a special technical specification. The process of further preparation of the mass is automatic, excluding errors in the composition of the final product. The operator follows readings on the display of the installation and controls the process of discharging the solution. Precise adherence to the technology and compliance with the proportions of the components allows obtaining eventually a monolithic slab with the required parameters.

3. Making an aluminum frame

The basis (frame) of the energy-efficient heater TeplEko is a frame made of aluminum profile. It is made at the factory area of argon welding. The reinforced aluminum profile gives the structure rigidity and protects it from physical effects. Also, a reinforcing frame serves as a mold, which is filled with a mortar mixture based on silica sand. Pre-placed in it a zigzag heater 0.4 kW. Protect the frame from corrosion in the paint chamber by evenly spraying two-component powder paint on its surface.

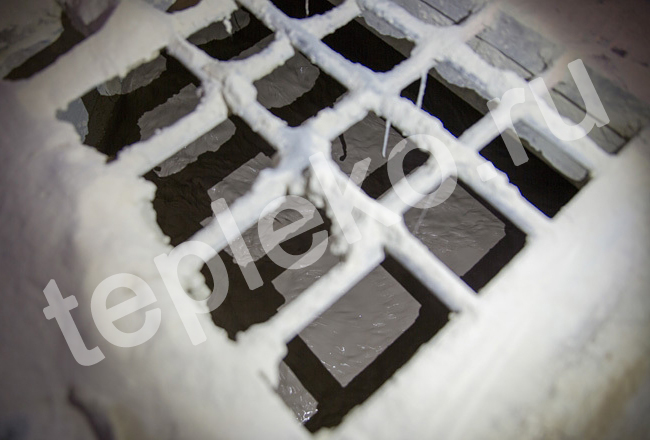

4. Forming and drying of products

At this stage, the TeplEko panel acquires its final shape. For this purpose, a mortar mixture of quartz sand and binding refractory components prepared in the RBU installation is distributed evenly inside the reinforcing frame laid on the vibrating table. Under the influence of vibration, the mortar is rammed and distributed over the frame shape while covering the heating element. The structural pattern on the monolith surface is created by laying a plastic mold on its surface. Then the product is placed in the drying chamber, where it goes through thermal drying for 4 days. The resulting monolith gets rid of moisture, acquires maximum strength and the necessary thermophysical parameters.

5. Calibration and grinding

To reduce porosity and give the surfaces an aesthetic appearance the dried monolithic panels are sanded. The final stage in the production of quartz heaters is quality control. In the quality control area, the company's employees check the performance of the products by turning them on for a long time and measuring the surface heating. In the presence of external defects (cracks, chips, etc.), and also violations of the device operation or production technology heaters are rejected. In the total volume of finished products, defective samples constitute only a fraction of a percent. All devices that have passed the inspection are packed and moved to the warehouse.

6. Packaging

For safe transportation, the TeplEko heater is delivered to consumers in a branded cardboard box parallelepiped. Simplifying logistical operations informative box demonstrates the quality of our products and the market prospects of TeplEko. The inscriptions on the tight packaging provide useful information about the technical characteristics of heaters, safety precautions, and recommendations for use. To protect the device and the packaging itself from mechanical and climatic influences, the company's employees pack the cardboard box in a protective film on a special machine.

What do the words “heater manufacturing” mean to the buyer? Mainly that the products will be available at a reasonable price. You just come to the warehouse and pick up your quartz heater. Or you can order its delivery from the warehouse to your home.

7. Laser cutting

The competitive advantage of Trading House "TeplEko" is its complete production cycle of both compact monolithic electric heaters and some of its accessories. Such as brackets, stands, etc. Components are manufactured in the laser cutting workshop with compressed oxygen and solid metal sheets. Laser machines allow you to perform metalworking with exceptional accuracy, using predetermined schemes and drawings. When used in combination with other metal processing methods (bending, welding, powder coating), a process is ideal. The products produced by TeplEko are characterized by flawless accuracy of linear dimensions and angles.

8. Gallery

In the above photos, you can get acquainted with the stages of the complete production cycle of innovative quartz heaters at Trading House "TeplEko". In the photo gallery, we tried to display the sequence of production operations, thanks to which the raw materials were transformed into finished products. TeplEko is a warehouse of raw materials, huge environmentally friendly production areas, many workshops (assembly, molding, painting, drying, argon welding, laser cutting, etc.). And also a warehouse of finished products, from where we ship demanded goods to dozens of brand stores across the country and abroad.